Metal Forming / Working Technology

35+ years of experience

Tooling Solutions, Plastic Mould Development, Fabrication, Assembly Engineering, etc

Hydraulics & Pneumatics, HVAC & Indl. Hardware

for various applications.

Your Partner for Metal Forming / Working Technology

UMS Engineering is an ISO IATF 16949-2016, ISO 45001-2015 and ISO 14001-2015 certified manufacturer for Automobile, Electrical, Medical, Air-Conditioning, Defence, Engineering, Tools, Equipment & Marine components.

Established in 1988, UMS is leading automotive pressed & formed components manufacturer in India, today. We deliver Sheet Metal, Precision Machined, Moulded, Fabricated, Platted & Powder Quoted parts & components along with Assembly Engineering Services.

We Design, Manufacture, Assemble & Value Engineer Parts & Components to meet your Engineering Requirements.

Our Services

Engineered Tooling Solutions

UMS is a complete solution for forming & punching on any material thickness.

Competence in bending, drawing, deep drawing, embossing, forging, trimming and deburring

Development & Manufacturing of Pressed Components

UMS is a complete solution for forming & punching on any material thickness.

Competence in bending, drawing, deep drawing, embossing, forging, trimming and deburring

Precision Machined Parts

We process machining parts that are highly accurate and consistent to exact specifications.

Process includes Turning, Milling, Grinding, Heat Treatment using all type of CNC machines

Assembly Engineering

UMS Assembly Engineering includes manufacturing & joining together components.

Our process includes Mechanical, Weld, Rivet, Sub & full Assemblies

Tooling Solutions & Parts

UMS uses cutting tools, machining strategy, component material, machine tool capability, fixtures and inventory management to manufacture your part with maximum effectiveness.

Value Engineering

UMS Value Engineering Solutions provide substitution of materials & methods with less expensive alternatives, without sacrificing functionality & quality.

Process includes review, functional analysis, evaluation, etc

Fabrication

UMS Engineering provides Customized Fabrication Solution to its clients.

Our process includes machining, cutting, welding, shearing, stamping, punching, etc

Plating & Powder Coating

UMS does powder coating as per customer requirement. We also do various types of surface coating and plating along with supplier partners.

Consultancy on Press Tool Strips Layout & Design

UMS designs product, provides high quality mold & manufacturing facilities

Types of molds process are Compression, Melt, Transfer, Injection, etc

Our Products

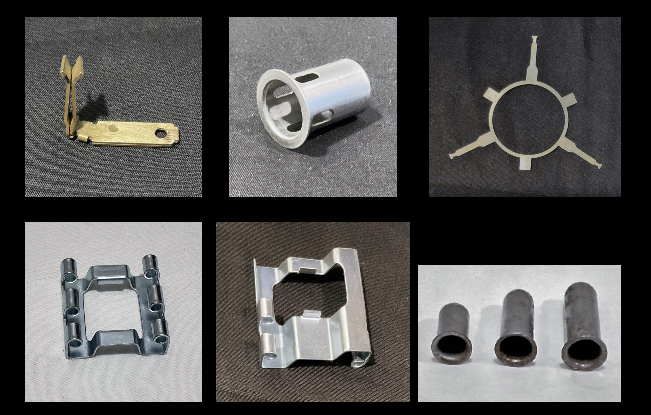

Sheet Metal Pressed & Formed Parts

UMS Stamping services ranges from short-run single hit stamping to high volume progressive die stamping.

Process includes Blanking, Piercing, Drawing, Conning, etc

Copper, Aluminium, Brass Parts

UMS has expertise in manufacturing high precision sheet metal pressed parts / components using Copper, Aluminium & Brass.

We fabricate a wide range of custom sheet metal parts, such as plates, fixtures, shields, brackets, etc ranging from 6mm thickness onward.

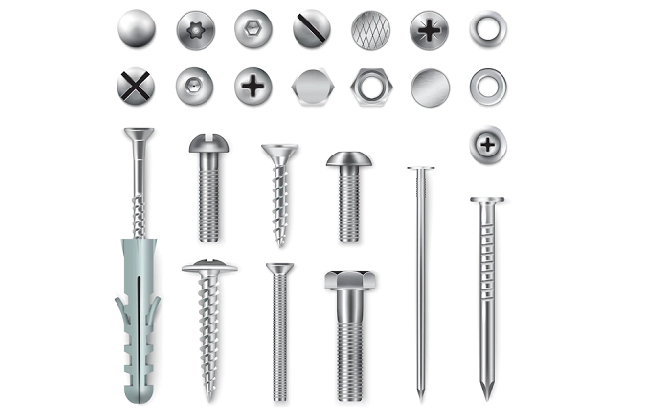

Deep Drawn Parts - Rivets

Rivet is made by forming sheet metal under compressive and tensile conditions to into a cavity.

We produce closed bottom, round, or irregularly shaped cup or cylinder rivets.

Specialty in Riveting Application

UMS manufacture an extensive range of Specialty Rivets.

We build special blind rivets that provides features as per specific material and application requirements.

Contact Clips, Spring Clips Contact Pins (Electrical Application) & Shielding Case

UMS manufacturers of contact clips, spring clips, contact pins, and shielding cases are specialized companies that produce these components for use in a wide range of electrical applications.

Assembly Engineering

UMS provides Full, Partial, Sub-assemblies using manual and semi-automated assembly line.

UMS ensure consistency and precision by leveraging our best-in-class assembly technologies

Engineering Tooling Solution

UMS provides Full, Partial, Sub-assemblies using manual and semi-automated assembly line.

UMS ensure consistency and precision by leveraging our best-in-class assembly technologies

Infrastructure

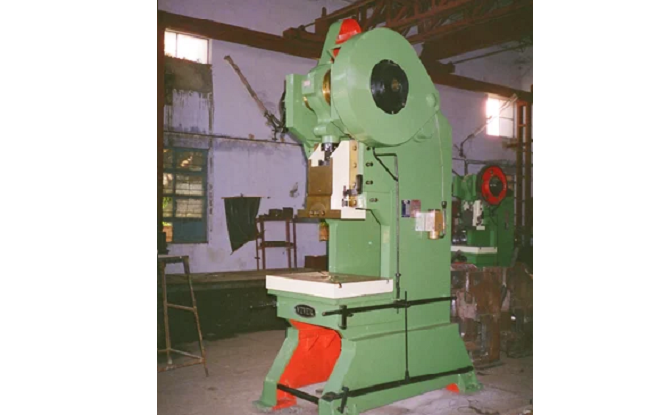

Press Shop

Presses are available in capacities of 5 to 100 tonnes ranging from ‘C’ types, Pillar, Inclinable, Hydraulic H Frame, Power Press & Pneumatic Power Press

Precision Machine Shop

Fabrication Shop

Presses are available in capacities of 5 to 100 tonnes ranging from ‘C’ types, Pillar, Inclinable, Hydraulic H Frame, Power Press & Pneumatic Power Press

Casting Shop

We always greatly appreciate demanding customers because they give us the momentum to continue to innovate.

Plastic Moulding

We always greatly appreciate demanding customers because they give us the momentum to continue to innovate.

Assembly Engineering

We always greatly appreciate demanding customers because they give us the momentum to continue to innovate.

Industries Served

Automobile & Automotive

Electrical & Electronic

Medical Instruments

Heating, Ventilation, and Air-Conditioning (HVAC) industry

Defence, Security & Military

Equipment Manufacturing

Marine Equipment

What our clients are saying about our company and products

Ernest Smith

Thomas Smith

Monica Smith

Ernest Smith

Great experience and impressive product. It was a very professional and technically competent job from the whole team.

Thomas Smith

Monica Smith

Ernest Smith

Great experience and impressive product. It was a very professional and technically competent job from the whole team.

Thomas Smith

Monica Smith

Great experience and impressive product. It was a very professional and technically competent job from the whole team.