ENGINEERED TOOLING SOLUTIONS

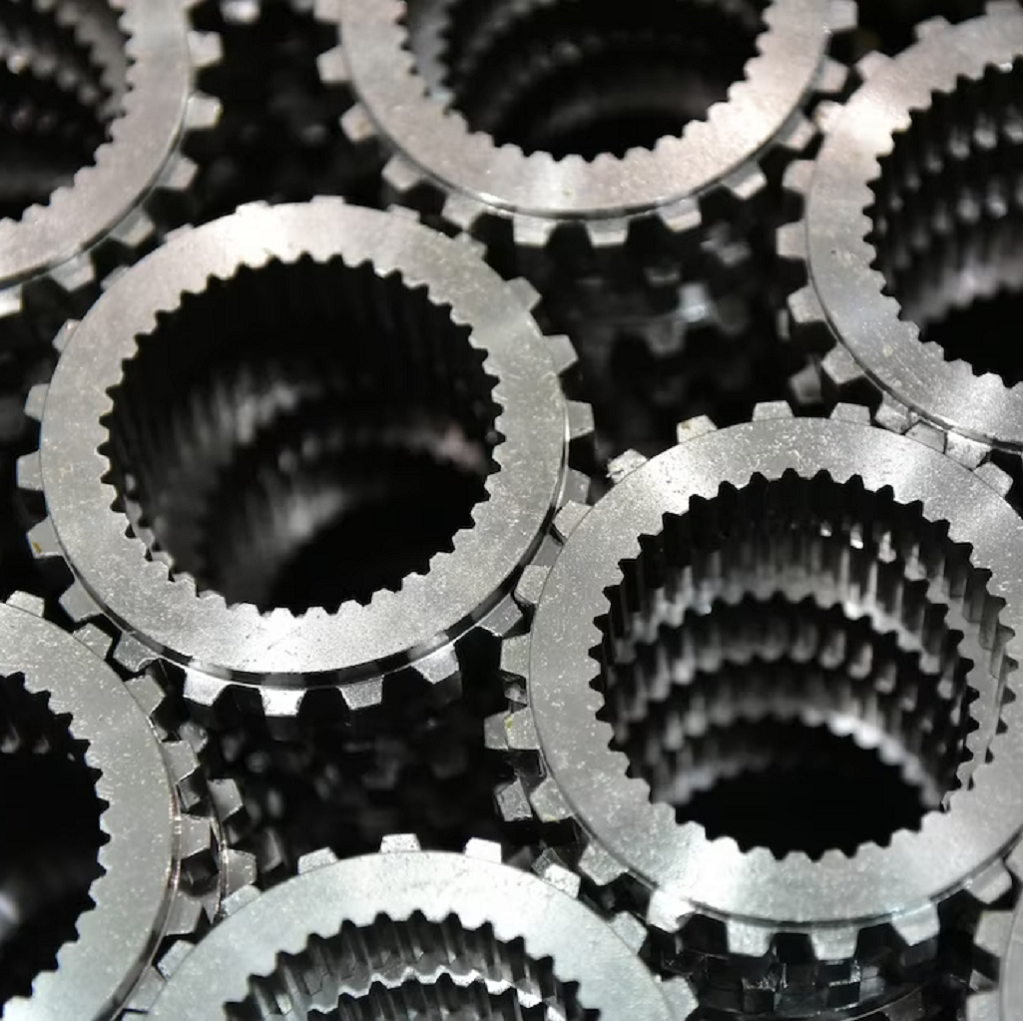

UMS as your specialist offers wide range of Press Tooling solution for punching, sheet metal and solid forging.

Pressing and punching solutions for all material thicknesses, materials and geometries using ideal pressing and punching centers be it automated or manual. We are manufacturer and service provider for punching and forming machines for our clients in India and globally. We have manufactured a broad range of product portfolio for our clients using very powerful and modern pressing and punching systems. we also offer our customers all our expertise and experience for their existing machines and value engineer their products.

We exercise stringent quality control measures for ensuring the accurate dimensions and mechanical properties of your products. We value time and ensure timely deliveries.

Press Tooling

- Progressive Press Tooling

- Deep Drawn Press Tooling

- High Speed Press Tooling

- Compound Press Tooling

Moulds

- Thermo Plastic

- Thermo Set

- Rubber

Wielding

- Special Jigs & Fixtures

- Customized Jigs & Fixtures

- Innovative Jigs & Fixtures

- Wielding for Jigs & Fixtures

Press Tooling

UMS as your specialist offers wide range of Press Tooling solution for punching, sheet metal and solid forging.

Pressing and punching solutions for all material thicknesses, materials and geometries using ideal pressing and punching centers be it automated or manual. We are manufacturer and service provider for punching and forming machines for our clients in India and globally. We have manufactured a broad range of product portfolio for our clients using very powerful and modern pressing and punching systems. we also offer our customers all our expertise and experience for their existing machines and value engineer their products.

We exercise stringent quality control measures for ensuring the accurate dimensions and mechanical properties of your products. We value time and ensure timely deliveries.

Services on complete Tool design and development

Progressive Press Tooling

Achievments:

- UMS to provide

- UMS to provide

- UMS to provide

Deep Drawn Press Tooling

Achievments:

- UMS to provide

- UMS to provide

- UMS to provide

- UMS to provide

High Speed Press Tooling

Achievments:

- Lorem ipsum dolor sit amet, consectetur adipiscing elit.

- Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Compound Tooling

Achievments:

- UMS to provide

- UMS to Provide

- UMS to Provide